Balancing Trade-Offs: Optimising Load & Haul Underground

Optimising load and haul operations is critical to achieving production, cost, and safety targets in underground mining. Yet assumptions like “more trucks equals more tonnes” doesn’t always hold true.

A recent study using idoba.sim, demonstrated that a data-driven, simulation-based approach can rapidly reveal trade-offs, inefficiencies, and optimal configurations - all within a few hours.

Configuring the Scenarios in idoba.sim

Our simulation team ran fourteen scenarios, including a total of 350 simulations. The first seven used one loader (LHD) working at a production level with an 800-tonne stockpile. Trucks travelled an 8 km one-way haul to the surface ROM, with one additional truck added per scenario.

Figure 1: Ore tonnes delivered to the surface by truck fleet and average tonnes moved per truck over the shift while servicing single loader and stope on one production level.

Initially, adding trucks increased total ore hauled:

· 383 tonnes with 1 truck

· 1425 tonnes with 4 trucks

However, by the sixth and seventh trucks, the gains plateaued:

· 1751 tonnes (6 trucks)

· 1745 tonnes (7 trucks)

Simulation Software Uncovers Congestion and Delays

To understand why performance declined, the team analysed time usage data and 3D visualisations in idoba.sim. The key issues revealed truck delays, driven by congestion in the decline.

Interpreting the Simulation Results

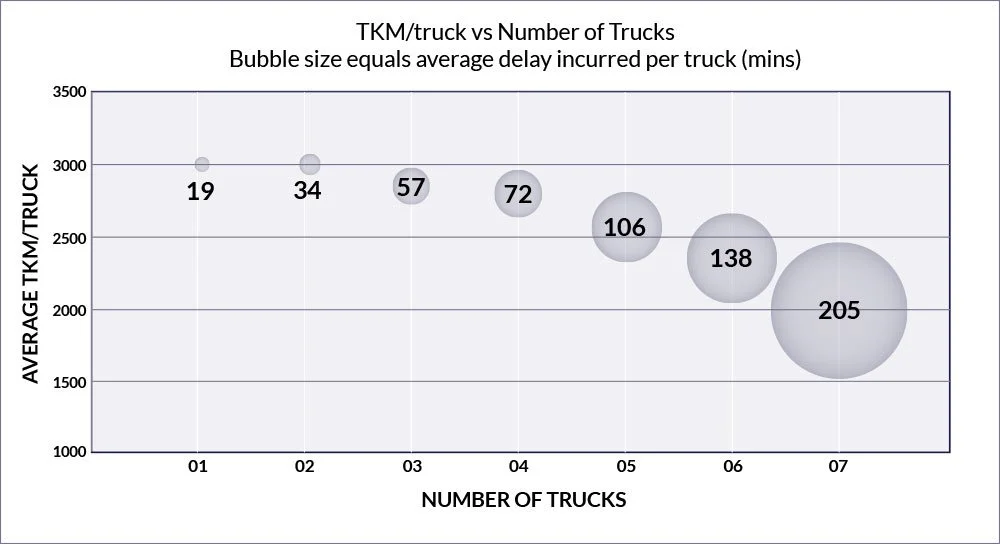

The simulation using idoba.sim revealed two root causes for increased truck delays.

Priority rules in the decline: Loaded trucks had right of way, forcing empty trucks to pull into remuck bays or stockpiles to wait.

Queueing at the loader: With only one LHD operating, trucks often sat idle near the level access.

Average delay per truck increased more than 10x, while efficiency per truck dropped significantly. More trucks meant more waiting.

Figure 2: TKM per truck vs number of trucks and the average delay minutes per truck over the shift while servicing single loader and stope on one production level.

Balancing Production Capacity and Fleet Size

In the second phase, the simulation added a second loader at production level. Trucks are now serviced both fronts—reducing congestion and better distributing the fleet.

Simulated Scenario Results With Seven Trucks

Total ore hauled increased from 1745 to 2287 tonnes

Avg tonnes/truck improved from 249 to 326

Truck delays dropped, and truck efficiency improved (TKM)

This Proved That Increasing Production Capacity, Not Just Fleet Size, Is the Key to Optimising Performance

The Benefits of Simulation Software

Using a cutting-edge simulation software like idoba.sim, offers mining engineers several benefits including;

Easy to use - Designed for engineers, idoba.sim is easy to use and delivers high-impact insights without the need for deep simulation expertise.

Fast scenario analysis – With idoba.sim users can quickly evaluate scenarios side-by-side to identify the potential impacts of new trade-offs to optimise resource allocation.

Reporting – At a glance monitor key performance metrics such as ore tonnes, truck tonnes, primary loader tonnes, TKM’s, and equipment delays in comprehensive reports, and charts.

Conclusion

This study dismantles the assumption that more trucks lead to better performance. In fact, after a point, they reduce system efficiency due to congestion and idle time.

Simulation revealed exactly where that tipping point occurs and how to solve it—not by adding more trucks, but by balancing load capacity and haul availability.

By using idoba.sim, the team not only found the fleet sweet spot, but proved how fast and cost-effectively mining professionals can address operational challenges in underground mining with our cutting-edge simulation software.

Ready to Unlock Underground Potential?

If you are ready to see first-hand how idoba.sim can provide you with actionable insights, that can significantly reduce costs and improve performance underground, then request a demonstration.

Subscribe to idoba Insights

If you’d like to hear more from idoba’s mining simulation experts, then subscribe to our monthly newsletter. In the next edition of idoba insights, we’ll uncover more valuable insights using our advanced simulation software, idoba.sim.

The impacts on loader productivity, when targeting trucking improvements

What happens when the stockpile becomes the bottleneck.

How tele-remote automation during shift change could maximise loader utilisation.

How big should the stockpile be?

What’s the ideal configuration to keep tonnes moving, when the crew’s not underground?